Product Details

BS series(Segment Core,Median Wire/Thick Wire,Median Speed)

BS-700series

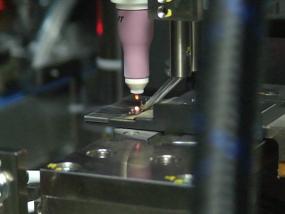

CNC Vertical Spindle Winding Machine for Connected Segment Core

BS-700series

CNC Vertical Spindle Winding Machine for Connected Segment Core

Basic Feature

- Best for winding thick wire for connected segment core.

- Target bobbin are set vertically following the gravity, are held with back-up and wound. This will provide speed and stable to in line winding.

- Specially designed JIGs for winding will provide no waste of wire winding.

- 2 set pieces will be wound at once.

Common Feature

- High-performance AC servo motor for all drive axes, dedicated winding controls for Bestec are installed.

- Wire routes are set to the height of workers view for better working property.

- Twist unit, coat peeling unit, terminal calking unit could be added as option.

- Automation lines are available with other process. Please contact for any interest.

MACHINE SPECIFICATIONS

| MODEL | BS-700 |

|---|---|

| WOUNDABLE ITEM | SEGMENT CORE (2 or 3pcs connected) |

| NUMBER OF WINDING HEAD | 2 |

| DRIVE AXES | 5-AXES |

| CONTROL | AC SERVO FOR ALL AXES |

| WINDING SPEED | 1000rpm |

| WOUNDABLE WIRE SIZE | φ0.6~φ2.5mm |

| WIRE CUT | AIR NIPPER |

| TENSION DEVICE | MAGNET BRAKE/ELECTRICAL/SERVO |

| MAIN POWER SUPPLY | AC 3-Phase 200V |

| PNEUMATIC SUPPLY | 0.40 – 0.60MPa |

| MACHINE SIZE (mm) ※ WITHOUT TENSION DEVICE | 1240W x 1700L x 2100H |

| MACHINE WEIGHT | 1800kg |

| LOAD / UNLOAD | MANUAL |

| SAFETY GUARD | FRONT AREA SENSOR/SAFTY COVER ETC… |

| OPERATION | ON TOUCH PANEL |